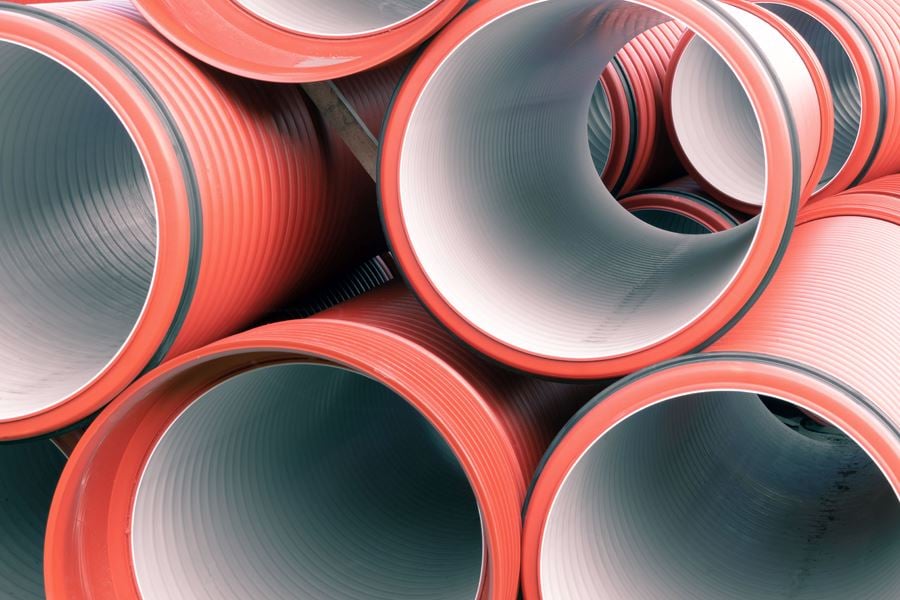

PVC

PVC (polyvinyl chloride) is one of the most widely used thermoplastic material. The environmental impact of PVC is associated primarily with emissions of harmful organic chemicals from the entire production chain, use of endocrine disrupters such as phthalates as plasticizers in soft PVC and challenges with waste management during production and end of life.

PVC is normally divided into two different categories due to its physical properties: rigid (hard) and soft PVC. Developments in environmental performance of PVC production includes replacements of heavy metal stabilisers like lead (Pb) and cadmium (Cd) which reduces the risk of spreading harmful chemicals when recycling PVC. Soft PVC has addition of plasticizers, where there has been a shift from phthalates to plasticizers that are less harmful to health.

How does the Nordic Swan Ecolabel contribute?

In general Nordic Ecolabelling restricts PVC in products where there are better environmental alternatives fulfilling the same function. We also set requirements for recycled content and/or restrict PVC production methods.

The requirements for the Nordic Swan Ecolabel focus on:

- Prohibiting or restricting PVC in many Nordic Swan Ecolabel product groups because of its health and environmental issues.

- Prohibiting PVC in products with short lifespan like packaging because today’s waste handling systems for these products do not sort the PVC for material recycling.

- Soft PVC is restricted for some product groups, where relevant, due to the risk of emission of plasticizers such as phthalates in the indoor air.

- Excluding mercury and diaphragm production methods for the manufacturing of chlorine gas for PVC production and also demanding specific recycled content, e.g., in the criteria for windows.

Environmental background

Globally, there are three different cell techniques (mercury, diaphragm and membrane) used in the production of chlorine gas for PVC production. Those may give rise to emissions of halogenated compounds and other substances like sulphate, sulphite and heavy metals to air and wastewater.

- The mercury cell technique (still used in some plants outside Europe) is a significant source of environmental pollution, and mercury can be contaminating air, water and waste.

- For plants using the diaphragm method, there can be emissions of asbestos to the surroundings, but also a potential workspace problem.

- For the membrane method, there is emissions of polyfluoroalkyl substances (PFAS).

Alternative stabiliser systems for rigid PVC (replacing Pb and Cd) include, in particular calcium-based formulations; PVC compounds containing these stabilisers now account for well over half of the European market according to Vinyl Plus article.

Plasticizers used in soft PVC are not bound to the polymer, they can leak out and be a source of harmful chemicals to humans and the environment – particularly phthalates such as DEHP, BBP, DBP and DIBP. A finished plastic product may contain up to 40% plasticisers. Today, new plasticisers are being developed to replace phthalates that have been a cause of concern due to their reproductive and endocrine disrupting effects.

The industry has moved to replacing hazardous low-molecular-phthalates (such as DEHP) with high-molecular phthalates such as DINP and DIDP or other plasticisers. These substances are not substances of very high concern under REACH, neither are they subject to restricted use by certain European Commission regulations, regarding children’s toys and feeding equipment.

Modern incineration plants in Europe have effective incineration and the emissions of polyaromatic hydrocarbons (PAH), benzo-a-pyrene, dioxins and furans has been significantly reduced.

Nevertheless, not all the Nordic countries allow incineration of used PVC due to the amount of neutralization waste generated by the purification of the flue gases. Denmark has waste legislation which states that all PVC must be sorted for material recycling if not then sent to landfill. PVC recycling systems are under development in various product areas. Hence Nordic Ecolabelling is looking at the possibilities of requiring recycling / take-back systems for specific product areas.